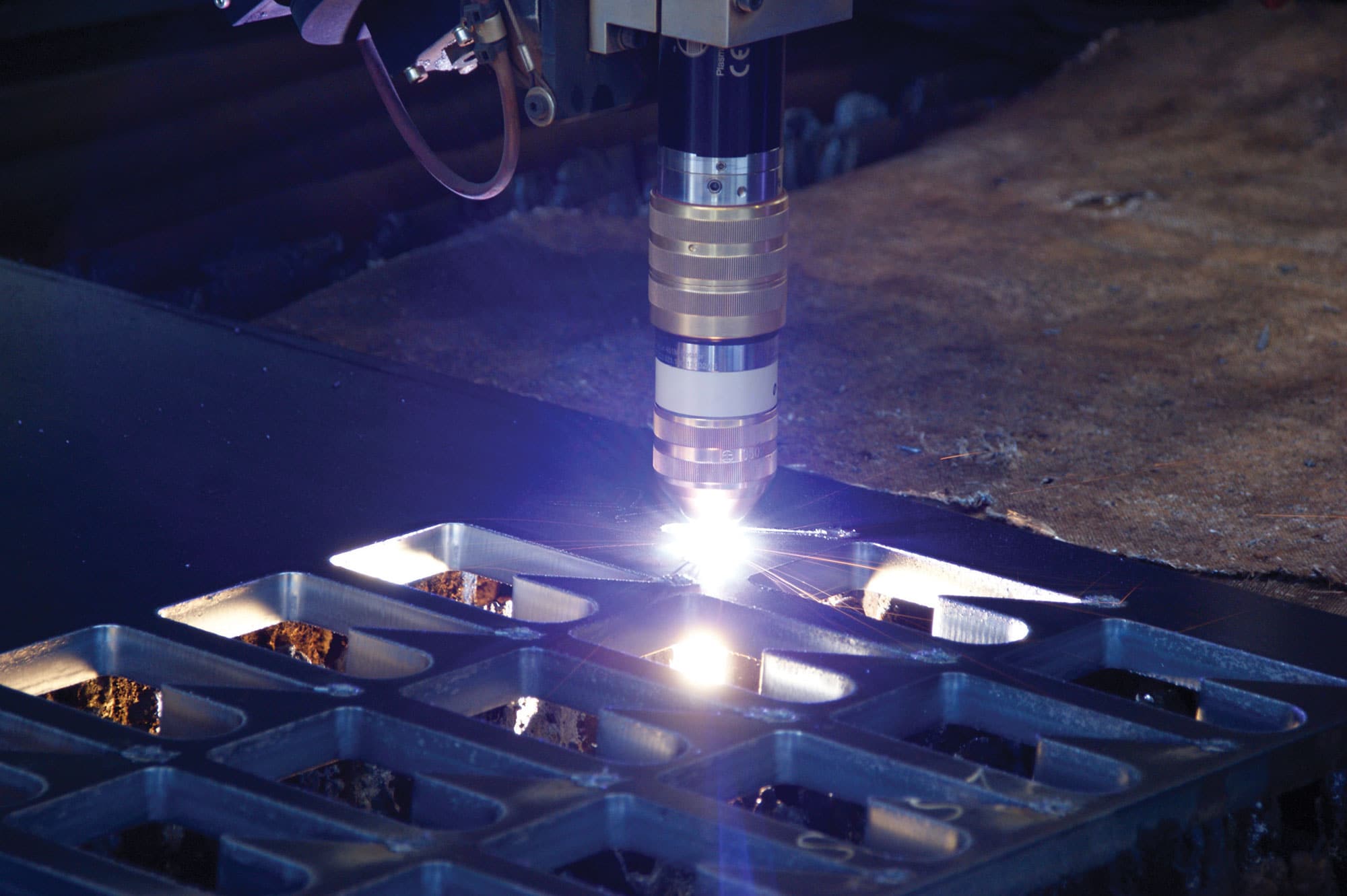

Modules

Expand your plasma cutter with one or more of our modules for optimum cutting results.

The HV sensor is a contact detection module designed to locate the position/surface of the material and determine the correct starting height.

The module works on the basis of ohmic contact with the plate or sheet and sends a signal when the torch comes into contact with the workpiece. This is done under a high DC test voltage, which also detects dirty and/or rusty surfaces.

Simply plug & play into Kjellberg power sources, but also universally compatible with other brands.

Flow compare is a module that detects small leaks in the cooling system early on. Electrode burning and perforated nozzles are also detected immediately. The plasma arc then stops immediately to prevent damage to the torch itself.

The ER6 module protects the torch when the plasma arc is interrupted on an edge, which can occur when the torch has to move off the material to cut the workpiece all the way through or when the location of the edge of the workpiece is not known (as is common with pressed parts).

In fact, the edge of the material is detected by how the plasma arc behaves. The arc is then stopped within a very quick time.

The arc voltage is a voltage signal of 0-250 VDC – far too high to be used directly on a robot or with a CNC machine.

The voltage is divided and completely galvanically isolated by an isolation amplifier. This results in a completely safe 0-10 V or 0-5 V signal that can be used on the CNC or robot.

The voltage magnifier is a module that acts like a magnifying glass on part of an analogue signal (e.g. the plasma arc voltage is transmitted as a 0-10 V signal). This results in a better resolution when the signal is inverted.

The typical plasma operating voltage is between 100 V and 175 V, or 4 V to 7 V for the 0-10 V signal. The magnifier boosts this by 3 V to produce a full 0-10 V signal. The module is also capable of inverting signals between 0-5 V, 0-10 V and -10-10 V.

The voltage magnifier can be used with plasma power sources, as well as in welding or with any other analogue signal.

Want to find out more? Ask our team for advice. We will come up with a turnkey solution that takes all the details into account, including customised plasma torches and electronic formulas.